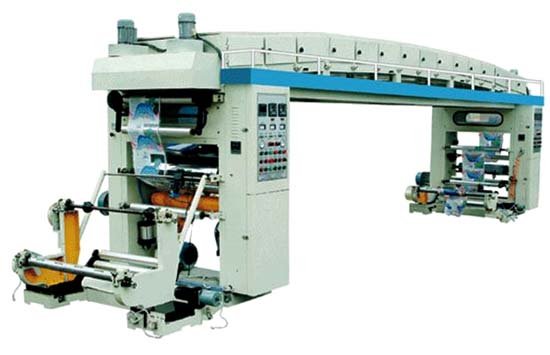

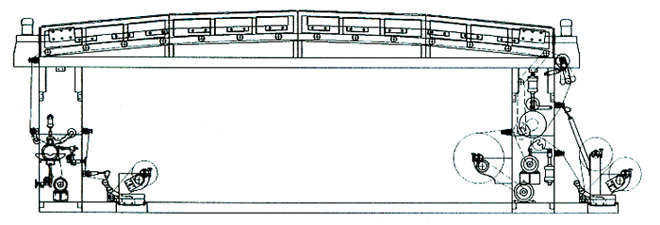

Usage:

It is suitable for BOPP, PET, and CPP, PVCD, Al-plated film, Al-tissue and the compound film and paper with the same properties. Its mechanical speed is70m/min.

Main transmission device:

The main transmission device adopts alternating current frequency transforming vector to control the electric machine. The speed of heat beat and rubber-plated roller and network can be adjusted. And it can assure the tightness and looseness for the films in the oven channels.

Material-feeding device:

Group 1and2 material-feeding devices adopt photoelectric correction deviation device while the roll feeding is controlled by magnetic-particle. The material-feeding devices of compound film adopts photoelectric correction device to control.

Rubber-plated device:

The mesh rollers control the amount of ink scrappers. While the rubber roller adopts double air cylinder to raise the pressure while the pressure can be adjusted freely .It is also equipped with film while stopping to lift automatically.

Structure of oven channel:

The temperature in the oven channel through four-pace intelligent thermo controller, equipped with inner cycling device. The materials-protecting roller and the heat beat can rotate synchronically.

Compound heat beat and impression roller device:

Compound heat beat and press roller device are heated through the hot oil to make the temperature of the heat beat average and to save electricity. Impression roller adopts dual air cylinder, while the pressure can be adjusted freely. Performance: Save electricity power.

Material-collecting device:

The Material-collecting adopts linkage material-collecting device, while the roll-collecting device adopts moment motor to collect the materials.

Main technical parameters:

|

Model type |

GFA-600A |

GFA-800A |

GFA-1100A |

|

Layers of complex |

2 |

2 |

2 |

|

Complex diameter(mm) |

600 |

800 |

1100 |

|

Packed diameter(mm) |

600 |

600 |

600 |

|

Adjustable range of complex linear speed (m/min) |

50-80 |

50-80 |

50-80 |

|

Max. Adjustable tempreture of dry oven(℃) |

80 |

80 |

80 |

|

Max. Adjustable tempreture of heat drum(℃) |

70 |

70 |

70 |

|

Tension ratio |

≤1/1000 |

≤1/1000 |

≤1/1000 |

|

Total power(kw) |

17 |

23 |

30 |

|

Weight(kg) |

3500 |

4000 |

4500 |

|

Overall dimensions (L×W×H)mm |

7500×1400×2500 |

7500×1400×2500 |

7500×1900×2500 |

|