|

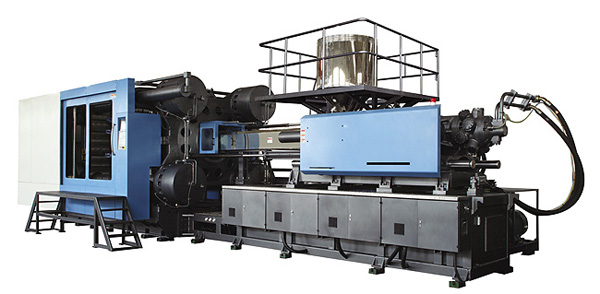

Features:

1, with short length and compact structure, the whole machine

occupies less floor space.

2. Dispense with mould adjustment, it is more convenient and faster to change

the mould.

3. with large opening stroke and colossal spaces between bars.

4. with elegant appearance.

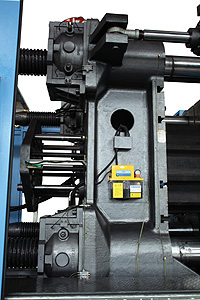

Clamping System:

1. Direct-press type of clamping structure with high-precision

pressure pick-up ensures accurate clamping forces.

2. Four bars are exerted equal force and have short stress segment; it brings

the clamping units good rigidity and long life expectancy.

3. Finite-elements-analyzed and optimized mould has good rigidity and small

deformation.

4. Oblique cylinder with rapid mould movement.

5. Dispense with mould adjustment, it reduces machine wear.

6. with multi-ways of hydraulic ejector system.

7. Automatic centralized lubrication system.

Injection System:

1. With double injection cylinders, it makes injection movement

more stable.

2.6 staged injection, 5 staged pressures maintaining, 3 staged pressures and

speed control in pre-plasticization.

3.2 Ways of initial control for pressure maintaining (location, time).

4. With anti cold burden start function.

5. We use large-toque oil hydraulic motor as pre-plasticization device.

6. Screw rotary speed detection devices.

7. Differential injection function increases the injection speed.

Hydraulic System

1.

With multi variable pumps & closed-loop control, the system is more energy

saving.

2. Unattached high pressure oil pump can create clamping forces of high

pressured rapidly.

3. Imported hydraulic parts and seal components.

4. Bypath oil filters of high-precision.

Safety System:

1. With anti-pinch injury function, it is speed- adjustable to

open or close the electric security gate.

2. Nozzle Injection protective cover can prevent plastic material ejected.

3. Double safety protection systems of hydraulic and electric interlock.

4. With safety tread inside and outside of mould, it protects personal safety.

Parameter:

|

Type

|

HD16800-17275

|

HD22000-21860

|

|

CLAMPING UNIT

|

T-shot platen

|

T-shot platen

|

|

Clamping force,

KN

|

16800

|

22000

|

|

Opening

Stroke, mm

|

1600-2300

|

1750

|

|

Max. daylight,

mm

|

3000

|

3550

|

|

Platen Size,

mm*mm

|

2200*2100

|

2670*2450

|

|

Space between

bars, mm*mm

|

1610*1450

|

1800*1650

|

|

Max. mold

height, mm

|

1400

|

1800

|

|

Min. mold

height, mm

|

700

|

850

|

|

Ejector

stroke, mm

|

380

|

420

|

|

Ejector force,

KN

|

330

|

450

|

|

INJECTION UNIT

|

|

|

|

Screw

diameter, mm

|

130 140 150 160

|

140 150 160 170

|

|

Screw L/D

ratio,

|

23.7 22 20.5 19.3

|

24 22 20.5 20.5

|

|

Injection

Pressure, Mpa

|

193 166 145 127

|

186 162 142 126

|

|

Shot volume,

cm3

|

8960 10391 11928 13672

|

11545 13254 15080 17024

|

|

Shot weight

(ps), g/OZ

|

7975/281 9248/326 10616/375 12079/426

|

10275/362 11796/416 13421/473

15151/535

|

|

Injection

rate, g/sec

|

940 1090 1250 1423

|

1251 1436 1633 1844

|

|

Plasticizing

Capacity, g/sec

|

138 147 165 176

|

149 163 172 181

|

|

Screw stroke,

mm

|

675

|

750

|

|

Screw speed,

rpm

|

95

|

72

|

|

POWER UNIT

|

|

|

|

Hydraulic

system pressure, Mpa

|

17.5

|

17.5

|

|

Pump motor

power, kw

|

55*2+15+7.5/32.7+41+41+41

|

55*3/41*4+14

|

|

Heater power,

kw

|

76

|

115

|

|

GENERAL

|

|

|

|

Dry circle

time, sec

|

|

|

|

Oil tank

capacity, L

|

2600

|

2800

|

|

Machine

weight, kg

|

75

|

156

|

|

Dimension

(LxWxH)

|

12.5*4.5*3.5

|

17.5*3.9*4.0

|

Note:

.Theory injection capacity = screw

diameter2×π/4×screw travel

.Actual injection capacity is the maximal weight of polystyrene (

PS ) raw material injected to air.

.When UPVC, PC, PMMA, PA and other engineering plastic material

are used, please let us know. When you need modifying parameters and functions

of the machine, please let us know also.

.According to demand of machine upgrade, we will change technical

parameters, configuration of some parts and service’s items without prior

notice.

.Photos are for reference only. If there is any difference with

actual products purchased, the real products are final.

.In normal condition six months warrantee for barrel & screw;

But using caustic or any recycling material is not is guaranteed.

|