|

Automatic Injection & Stretch Blow Molding Machine

—One Step Container Forming Solution Expert

Environmental protection

to

reduce the work on operation, packaging, handling and storage, and cut down

energy consumption, and with compact structure to occupy less space;

Cleanness

one step on product forming to avoid more pollution;

Reliability

by using one step on forming to reach a minimum rate of defective products;

Good forming

precise positioning on bottle mouth, light weight on bottles, better

parting line; adapting to abnormal shapes and high quality requirements on

appearance..

Information

Along

with the increasing demand of the quality on packaging containers for food,

pharmaceutical, cosmetic and high-grade daily necessities, the automatic

injection & stretch blow molding technology is adapted to the needs of the

market. By using this technology, the product is finished in one step from

preform injection, forming by stretch & blow, to ejection. The production

is of no flash, no deflating material, avoiding double pollution, and the

products have good quality on appearance, smooth mouth and excellent sealing.

The technology has the advantages of realizing light weight on production

process, with high speed, high efficiency, and energy saving etc..

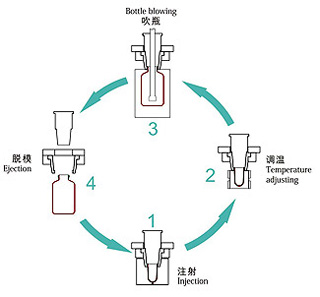

Working principle

adopting

vertical rotating mechanism, and with four stations equidistributed on the

rotary table, which are injection, temperature adjusting, stretch & blow,

and releasing. Four process of preform injection, temperature adjusting on

preform, forming by stretch & blow, and releasing are finished at the same

time. No additional process needed and one-step injection stretch blow molding

is realized.

Servo motor positioning

system

the

rotary table mechanism adopts servo motor control system with high precision.

Rotary table is sensitive and of accurate positioning.

Energy saving

power system

adopts

energy-saving variable pump or servo motor system and saves the electricity

consumption up to 30%-60%.

Compressor air

system

Recycles

the used high pressure air during bottle blow molding and reduces air

consumption. (Optional)

Standard hot

runner system

No

replacement of hot runner system when mold changing which reduces the mold

cost.

Parameters

|

Type

|

HDLD18V1

|

|

INJECTION UNIT

|

|

|

Screw

diameter, mm

|

36 42 46

|

|

Screw L/D,

Ratio

|

23.3 20.4 18

|

|

Injection

Pressure, Mpa

|

259 190 159

|

|

Shot volume,

cm3

|

183 249 299

|

|

Shot weight

(ps), g

|

163 222 267

|

|

Shot weight

(pet), g

|

201 275 330

|

|

Shot weight

(pc), g

|

186 255 305

|

|

Shot weight

(ppsu), g

|

200 272 328

|

|

Shot weight

(pp), g

|

140 190 229

|

|

Screw stroke,

mm

|

180

|

|

Screw speed,

rpm

|

225

|

|

CLAMPING UNIT

|

|

|

Injection mold

clamping force, KN

|

165

|

|

Injection mold

clamping stroke, mm

|

385

|

|

Injection mold

height, mm

|

420

|

|

Blowing mold

clamping force, KN

|

140

|

|

Blowing mold

stroke, mm

|

110-190

|

|

Shape of

blowing mold platen, mm

|

350*265

|

|

Min. mold

height of blowing mold, mm

|

80

|

|

Max. Opening

stroke of blowing mold, mm

|

270

|

|

POWER UNIT

|

|

|

Hydraulic

system Pressure, Mpa

|

16

|

|

Pump motor

power, KW

|

22.5

|

|

Heater power,

KW

|

12.5

|

|

Blowing air

pressure. Mpa

|

3.0-3.5

|

|

Pneumatic

system pressure, Mpa

|

0.8

|

|

GENERAL

|

|

|

Oil tank

capacity, L

|

460

|

|

Machine

weight, Ton

|

6.1

|

|

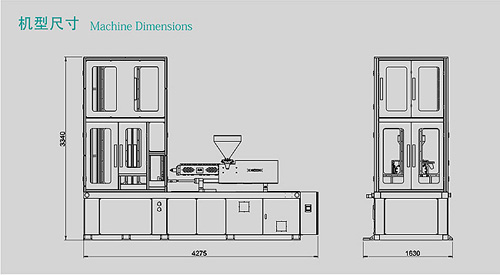

Machine

dimensions(L*W*H)

|

4275*1630*3340

|

Product

specifications

|

Mold cavity

NO.

|

Max. capacity,

L

|

Max. screw

thread diameter, mm

|

Max. outer

diameter of bottle neck, mm

|

Max. outer

diameter, mm

|

Max. Height.

mm

|

|

1

|

2.5

|

83

|

80

|

115

|

250

|

|

2

|

1.5

|

62

|

60

|

100

|

250

|

|

3

|

0.9

|

45

|

40

|

70

|

250

|

|

4

|

0.4

|

38

|

33

|

55

|

250

|

Remarks:

According to upgrading of machine, we will change technical parameters,

configuration of some parts and service’s items without further notice.

|