|

Features:

Energy

saving |Excellent performance|Reducing

production costs|Easy to operate

·Using variable pump hydraulic system to lower power consumption.

·Faster response, higher repetition, better stability.

·Injection molding with two materials or double colors at the same time, which

can reduce the cost of the technology and the human resources.

·Very easy to set parameters and adjust hydraulic system with the digit

control.

Working

principle

The

injection molding machine injects the first material into the mould and the

plastic takes the shape. After the mould is open, the movable rotary mould

platen turns around with the other work pieces by 180。then

the machine makes the second injection after the injection nozzles is directed

at the cavities of the mould and the mould is closed, and then finally takes

shape; Or the first material injection and the second material can be done at

the same time to take shape.

Parameter:

|

Type

|

HD1300-196

|

HD2000-1310

|

HD4000-1664

|

|

CLAMPING UNIT

|

|

|

|

|

Clamping

force, KN

|

1300

|

2000

|

4000

|

|

Opening

Stroke, mm

|

400

|

490

|

710

|

|

Max.

daylight, mm

|

850

|

1060

|

1440

|

|

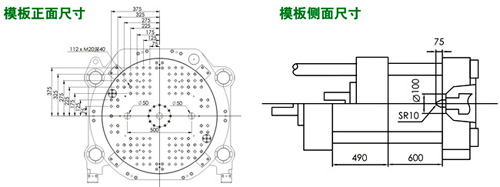

Platen

Size, mm*mm

|

1060*1060

|

1252*900

|

1450*1100

|

|

Space

between bars, mm*mm

|

720*410

|

910*510

|

1110*720

|

|

Max.

mold height, mm

|

450

|

600

|

750

|

|

Min.

mold height, mm

|

130

|

150

|

200

|

|

Ejector

stroke, mm

|

120

|

150

|

180

|

|

Ejector

force, KN

|

2*49

|

2*65

|

2*77

|

|

INJECTION UNIT

|

|

|

|

|

Screw

diameter, mm

|

26 28 30

|

30 36 42

|

42 46 52

|

|

Screw

L/D ratio,

|

22.6 21 19.6

|

20 20 17

|

22 20.5 18

|

|

Injection

Pressure, Mpa

|

234 202 155

|

266 185 136

|

213 177 139

|

|

Shot

volume, cm3

|

63 73 96

|

113 163 222

|

284 340 435

|

|

Shot

weight (ps), g/OZ

|

60/2 69/2.4

91/3.2

|

106/3.7

153/5.4 208/7.2

|

267/9.4 320/11.3

409/14.4

|

|

Injection

rate, g/sec

|

64 73 84

|

54 78 106

|

105 126 161

|

|

Screw

stroke, mm

|

120

|

160

|

205

|

|

Screw

speed, rpm

|

230

|

210

|

210

|

|

POWER UNIT

|

|

|

|

|

Hydraulic

system pressure, Mpa

|

16

|

16

|

16

|

|

Pump

motor power, kw

|

11+11

|

14+14

|

32.7+32.7

|

|

Heater

power, kw

|

7

|

6

|

22

|

|

GENERAL

|

|

|

|

|

Oil

tank capacity, L

|

210

|

180

|

630

|

|

Machine

weight, kg

|

6

|

8

|

15

|

|

Dimension

(LxWxH)

|

5*1.6*1.8

|

5.2*1.7*1.9

|

7.2*2.2*2.3

|

|