|

Features:

·Fast

response proportional variable pump matches the hydraulic output and the need

of running of the machine, without lost of high pressure over flow, which can

save 25-50% power comparing with the fixed pump machine.

·Special design screw & barrel for Bakelite, which is made by high strength

bi-metallic steel with special treatment, with the characteristic of good

corrosion resistance & good abrasion resistance.

·Oil cooling device in the screw & barrel insures the precision of the

temp.

·Mould open and exhaust

·Change of screw & barrel can be used as standard injection mold machine.

·Upgraded size of the injection motor with increase of injection pressure

achieves better plasticization.

·Special design heat resolution plate is adopted in the mould platens.

·2 sets of interface port for the mould temp. control is provided with computer

control

·High precision 0.1mm can be achieved with the electric sensor control

·Automatic mould adjustment is control by computer by entering the clamping

force directly.

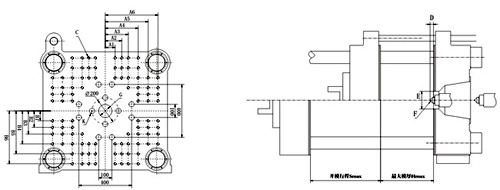

Mould platen Size

Technical

Parameters:

|

Type

|

HD900-300

|

HD1200-380

|

HD1600-730

|

|

CLAMPING UNIT

|

|

|

|

|

Clamping

force, KN

|

900

|

1200

|

1600

|

|

Opening

stroke, mm

|

320

|

350

|

440

|

|

Max. daylight,

mm

|

650

|

720

|

910

|

|

Platen size,

mm*mm

|

540*540

|

610*610

|

705*705

|

|

Space between

bars, mm*mm

|

360*360

|

410*410

|

460*460

|

|

Max. mold

height, mm

|

330

|

370

|

470

|

|

Min. mold

height, mm

|

100

|

115

|

130

|

|

Ejector

stroke, mm

|

100

|

100

|

140

|

|

Ejector force,

KN

|

34

|

42

|

49

|

|

INJECTION UNIT

|

|

|

|

|

Screw

diameter, mm

|

30 36

|

40 46

|

46 52

|

|

Screw L/D

ratio

|

16 15

|

16 15

|

16 15

|

|

Injection

Pressure, Mpa

|

266 185

|

166 125

|

177 139

|

|

Shot volume,

cm3

|

113 163

|

226 299

|

341 435

|

|

Shot weight

(ps), g/OZ

|

136/4.8

195/6.9

|

271/9.6

359/12.7

|

409/14.4

522/18.4

|

|

Injection

rate, g/s

|

71 102

|

113 150

|

161 206

|

|

Plasticizing

capacity, g/s

|

13 19

|

22 30

|

28 38

|

|

Screw stroke,

mm

|

160

|

180

|

205

|

|

Screw speed,

rpm

|

184

|

180

|

204

|

|

POWER UNIT

|

|

|

|

|

Hydraulic

system Pressure, Mpa

|

17.5

|

17.5

|

17.5

|

|

Pump motor

power, KW

|

11

|

11

|

15

|

|

Mold heater

power, KW

|

6

|

7.8

|

9.8

|

|

GENERAL

|

|

|

|

|

Dry-cycle time

Sec

|

1.5

|

1.5

|

1.8

|

|

Oil tank

capacity, L

|

180

|

200

|

260

|

|

Machine

weight, Ton

|

2.8

|

3.2

|

4.5

|

|

Machine dimensions

(L*W*H)

|

3.8*1.1*1.7

|

4*1.2*1.8

|

4.8*1.3*1.8

|

|

Type

|

HD2000-934

|

HD2880-1341

|

HD3300-1902

|

|

CLAMPING UNIT

|

|

|

|

|

Clamping

force, KN

|

2000

|

2880

|

3300

|

|

Opening

stroke, mm

|

490

|

550

|

6000

|

|

Max. daylight,

mm

|

1010

|

1130

|

1270

|

|

Platen size,

mm*mm

|

775*755

|

850*850

|

985*985

|

|

Space between

bars, mm*mm

|

510*510

|

610*610

|

670*670

|

|

Max. mold

height, mm

|

520

|

580

|

670

|

|

Min. mold

height, mm

|

200

|

250

|

270

|

|

Ejector

stroke, mm

|

140

|

145

|

180

|

|

Ejector force,

KN

|

65

|

77

|

77

|

|

INJECTION UNIT

|

|

|

|

|

Screw

diameter, mm

|

52 60

|

60 68

|

68 75

|

|

Screw L/D

ratio

|

16 15

|

16 15

|

16 15

|

|

Injection

Pressure, Mpa

|

180 135

|

169 132

|

169 139

|

|

Shot volume,

cm3

|

520 693

|

792 1017

|

1126 1370

|

|

Shot weight

(ps), g/OZ

|

624/22.0

831/29.3

|

950/33.5

1220/43.0

|

1351/47.7

1643/58.0

|

|

Injection

rate, g/s

|

199 265

|

302 387

|

396 481

|

|

Plasticizing

capacity, g/s

|

38 55

|

50 65

|

70 85

|

|

Screw stroke,

mm

|

245

|

280

|

310

|

|

Screw speed,

rpm

|

173

|

165

|

174

|

|

POWER UNIT

|

|

|

|

|

Hydraulic

system Pressure, Mpa

|

17.5

|

17.5

|

17.5

|

|

Pump motor

power, KW

|

18.5

|

22

|

30

|

|

Mold heater

power, KW

|

11.5

|

14.2

|

18

|

|

GENERAL

|

|

|

|

|

Dry-cycle time

Sec

|

1.8

|

3

|

3.2

|

|

Oil tank

capacity, L

|

340

|

420

|

460

|

|

Machine

weight, Ton

|

5.8

|

8.2

|

10.8

|

|

Machine

dimensions (L*W*H)

|

5.75*1.4*2.1

|

6.2*1.5*2.2

|

6.8*1.6*2.3

|

|