|

Features:

.Toggle

mould clamping mechanism guarantees big clamping force, no expansion of mould,

no increase of high pressure air consumption.

.High-performance

chain driven by servo motor ensures stable, fast and accurate operation.

.High-pressure

cylinder sealing and independent controlled stretch bar guarantees reliable

sealing and accurate stretching.

.Automatic

perform handling equipment and robots for perform loading & take-out make

production process fully automatic.

.Latest

high speed PLC and Chinese-English HMI are adopted. The time setting can be

accurate in 0.01 second. It makes the operation more easy and the technical

setting more accurate.

.High

quality pneumatic parts are imported from Europe or Japan. Fast feedback solenoid

valve (from Germany) is adopted in high-pressure blowing. It ensures the second

blow time accurate and controllable.

IR lamp which is most efficient for PET

heating, is fully considered for lower power consumption and higher production

efficiency.

Technical

Parameter:

|

Specification

|

HDSBL280-1

|

HDSBL280-2

|

HDSBL280-3

|

|

Clamping

Force, KN

|

280

|

280

|

280

|

|

Mold Height,

mm

|

180-240

|

180-240

|

180-240

|

|

Mold Open

Stroke, mm

|

195

|

195

|

130

|

|

Bottle

Capacity. Ml

|

5000

|

2000

|

600

|

|

Reference

Output, BPH

|

700

|

1800

|

3600

|

|

Stretch Bar Stroke,

mm

|

410

|

410

|

410

|

|

Max. Bottle

Neck, mm

|

120

|

90

|

38

|

|

Max. Diameter

of Bottle, mm

|

180

|

130

|

70

|

|

Max. Height of

Bottle, mm

|

300

|

280

|

280

|

|

Mold

Cavities/Central Distance, c/mm

|

1/-

|

2/152.4

|

3/76.2

|

|

Power Rating.

KW

|

38

|

38

|

38

|

|

Power

Consumption, KW

|

<20

|

<20

|

<20

|

|

Operation

Pressure/Consumption, Mpa/m3/min

|

0.8/2.0

|

0.8/2.0

|

0.8/2.0

|

|

High

Pressure/Consumption, Mpa/m3/min

|

3.0/2.0

|

3.0/2.0

|

3.0/2.0

|

|

Machine

Dimension (L*W*H)

|

2650*1600*2000

|

2650*1600*2000

|

2650*1600*2000

|

|

Machine

Weight, KG

|

2050

|

2050

|

2050

|

Remarks:

According to upgrading of machine, we will change technical parameters,

configuration of some parts and service’s items without further notice.

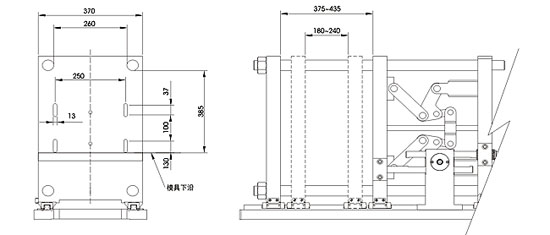

Mould platen

size:

|