|

The

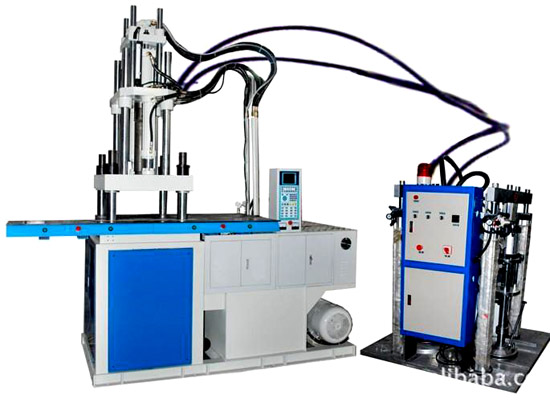

main features of the machine are as follows: Self research and development

(20/200l) LSR feeding machine and the selected 2KM machine which is made in

Germany.

Multi segments precise mould heating temperature control. LSR special use oil

pressure water cooled sealed nozzle, pipe assembly.

Sandwich insulated fiber-board. Which includes insulation board and insulating

fiber-board? This can avoid the problem of use life and stability of the

machine as well as unnecessary energy waste caused by heat transfer of the

mould.

|

Type

|

HDTY-400.DS.LSR

|

|

INJECTION UNIT

|

|

|

Screw

Diameter, mm

|

32, 36

|

|

Injection

Pressure, Kg/cm2

|

1662, 1313

|

|

Theoretical

Shot volume, cm3

|

96, 122

|

|

Max. Shot

Weight, g/Oz

|

186/3.0,

109/3.8

|

|

Injection

Rate, cm3/sec

|

58, 73

|

|

Temperature

Control, ZONE

|

3

|

|

Material

Hopper Capacity, L

|

20

|

|

CLAMPING UNIT

|

|

|

Clamping

Force, T

|

40

|

|

Opening Force,

T

|

8.3

|

|

Distance

Between Tie Bare, mm

|

415*250

|

|

Min Mold

Height, mm

|

150

|

|

Opening

Stroke, mm

|

200

|

|

Max. Open

Daylight, mm

|

350

|

|

Ejector Force,

T

|

1.3

|

|

Ejector stoke,

mm

|

40

|

|

POWER UNIT

|

|

|

Max. Hydraulic

Pressure, Kg/cm2

|

140

|

|

Pump Output, L

|

160

|

|

Pump Motor

Power, Kw

|

5.5

|

|

Barrel Heating

Power, Kw

|

4.1

|

|

Total Wattage,

Kw

|

9.6

|

|

GENRAL

|

|

|

Machine

Weight, T

|

1.6

|

|

Machine

Dimensions(L*W*H), m

|

1.9*1.1*2.7

|

|

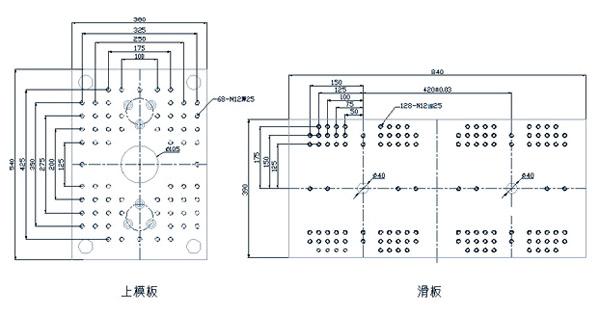

Slide Plater

Stoke, mm

|

420

|

|

20kg Feeder

Size, m

|

0.8*0.4*1.95

|

|